On the verge of a green and clean era in the metal tool industry

Expensive metalworking fluids are no longer needed to cool and lubricate workpieces and cutting tools in the machine tool industry. Instead, there is now a proven green and clean method, EcoCooling, that uses only ionised and cooled air and has none of the environmental hazards and costs related to oil-based fluids.

EcoCooling is the result of long-term, interdisciplinary R&D from the same team that developed the technology behind Amazon’s ground-breaking family of front-lit Kindle devices. Now the group of scientists, engineers and experienced businesspeople from various disciplines has developed a dry, clean and environmentally friendly method to lubricate metal workpieces with ionised and cooled air without using any emulsions.

“Workshops have wanted to get rid of fluids and many have tried to find a solution to the problem, but with poor results”, says Leo Hatjasalo, co-founder and CEO of EcoCooling. “Now we have the answer to this demand, since EcoCooling can be used even with the hardest known metals like chrome, titanium and tungsten carbides.”

Big market

The global market value for metalworking fluids is estimated at approximately $12 billion (€10 billion) this year. It is growing steadily, with estimates for the global market value for machine tools expected to grow from $120 billion (€106 billion) to $150 billion (€133 billion) in five years’ time. The growth is driven, for example by the accelerating need for components in the aerospace, automotive and transport sectors.

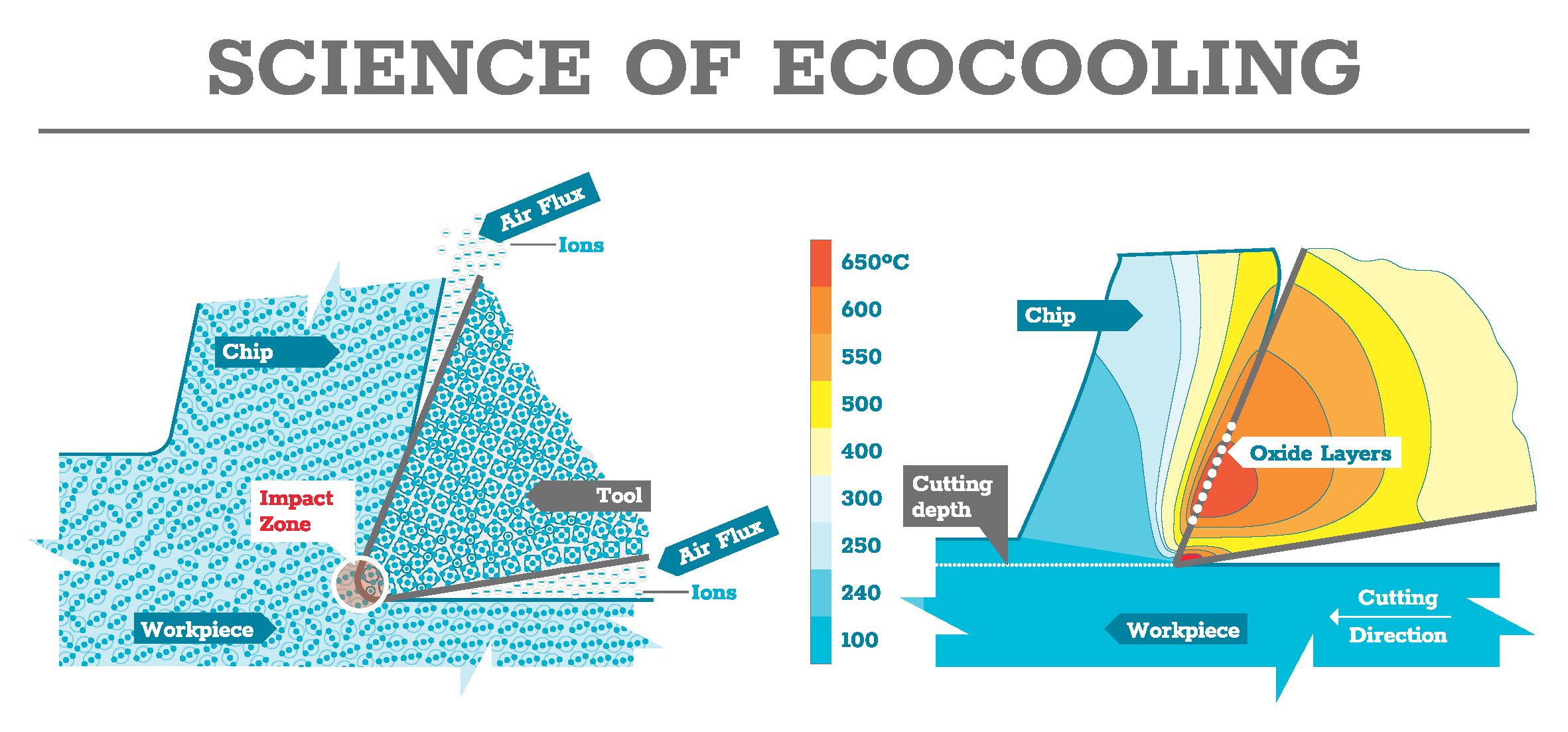

“EcoCooling is based on the fact that ionised air penetrates the cutting zone and forms a dry lubricant that decreases cutting friction and generated heat, at the same time speeding up the oxide layer formation”, Hatjasalo explains. “The process is patented on all continents, and at the moment we are validating it to include all types of machine tools.”

Hatjasalo emphasizes that EcoCooling is not only a way to cut down the costs of emulsions, but also a way to improve productivity through higher cutting speed, reduced wear of cutting tools and minimised maintenance costs.

“Since the metal chips are not contaminated by any fluids, they can also be fully recycled without cleaning”, he says. “Another big advantage is that it eliminates toxic fluid waste and fumes, in addition to minimising CO2 emissions, since no oil is used.”

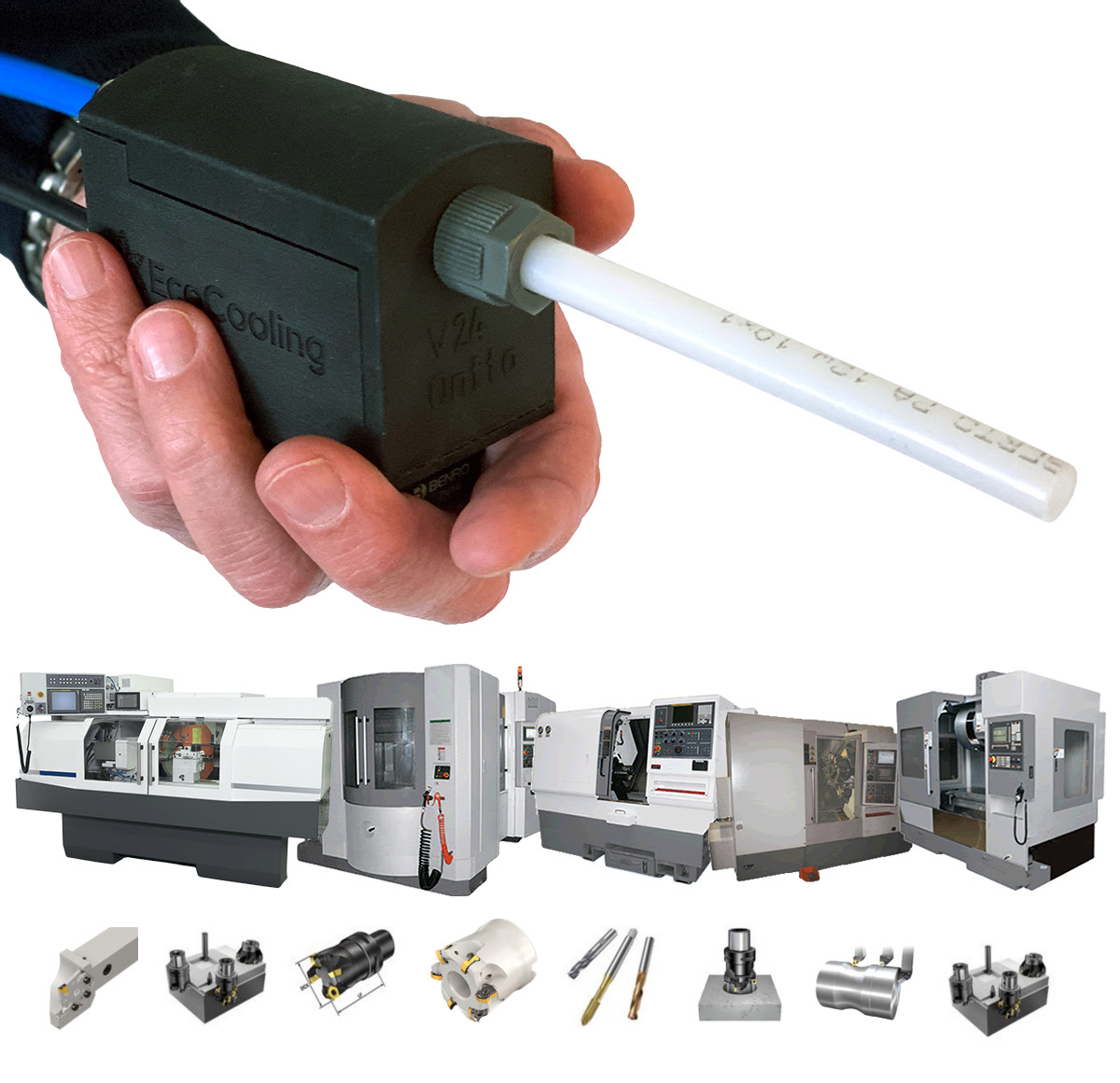

The technology makes it possible to build smaller and cheaper metalworking machines, since the EcoCooling unit is very compact in size.

“The unit does not need any service and it has proved to prolong the lifetime of the cutting tools significantly”, Hatjasalo says. “The system can also be easily retrofitted to older machine tools.”

The big leap is still ahead

During the past few years, EcoCooling has been successfully trialled in numerous commercial tests in demanding surroundings internationally. Now that the process has proved to give excellent results, big savings and substantially less environmental impact, the aim is to create a versatile EcoCooling product family that includes all machine tools in addition to just turning machines.

“We are also planning to integrate the system to suit different CNC machine tools and to create optimal solutions for all machine tools and workshop environments”, Hatjasalo says. “However, for that purpose we need more funding than we can raise on our own. Therefore, the next step is to find an industrial partner to help us to commercialize EcoCooling globally and to develop the ways the technology can be used.”

Comment on this article below or via Twitter @IoTGN