Cognex presents decoding technology in a new compact barcode reader

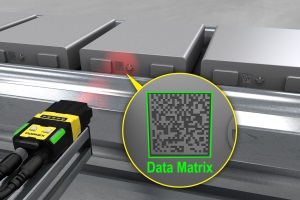

Cognex Corporation introduces the DataMan 280 series of fixed-mount barcode readers, engineered to solve a broad range of ID applications, including tough 1D, 2D, and Direct Part Mark (DPM) code applications in manufacturing and logistics.

“Cognex specialises in decoding the most difficult to read barcodes at the highest speed and accuracy, says Carl Gerst, Cognex’s executive vice president of products and platforms. “Optimised with our latest patented decoding algorithms, the DataMan 280 combines advanced technology from Cognex’s premium ID platforms into a compact and cost-effective housing.”

A powerful and operator-friendly reader to speed up production and throughput

The DataMan 280 features a high-resolution sensor combined with a dynamic image formation system to improve code handling and coverage. This technology, along with connectivity options for today’s Industry 4.0 manufacturing needs, allows users to read complex barcodes reliably while improving overall equipment effectiveness (OEE) and throughput.

Combined with Cognex Edge Intelligence (EI), DataMan 280 provides advanced Industry 4.0 features like easy web browser connectivity, device management, performance monitoring and fast image offload. It allows users to configure multiple devices at once and begin trending important system performance metrics in minutes. Facility managers can identify trends and intervene quickly when dips in performance are spotted.

Modular configurations and future-proof design for any code reading application

The modular hardware including field-interchangeable lights and lenses and latest software algorithms can

be configured to solve any barcode reading challenge. DataMan 280 can be configured straight or in right

angle for tight spaces and is compatible with most accessories of the DataMan 260 series for easy

upgrading. For applications with increased field of view and multi-side scanning at high speeds, multiple

readers can be deployed together.

The DataMan 280’s modular hardware and software make it ideal for label-based and DPM code reading applications in a wide range of industrial environments. Examples include decoding difficult DPM codes on challenging surfaces of automotive parts, reading and tracking small DPM codes on medical devices or reliably reading barcodes on high-speed packaging lines. Other typical tasks of the DataMan 280 include simultaneous reading of multiple codes, presentation scanning and label-based 1D and 2D code reading on pallets behind reflective foil.

For more information, visit here.

Comment on this article below or via Twitter @IoTGN