New rail sensor system to be launched by Vortex IoT

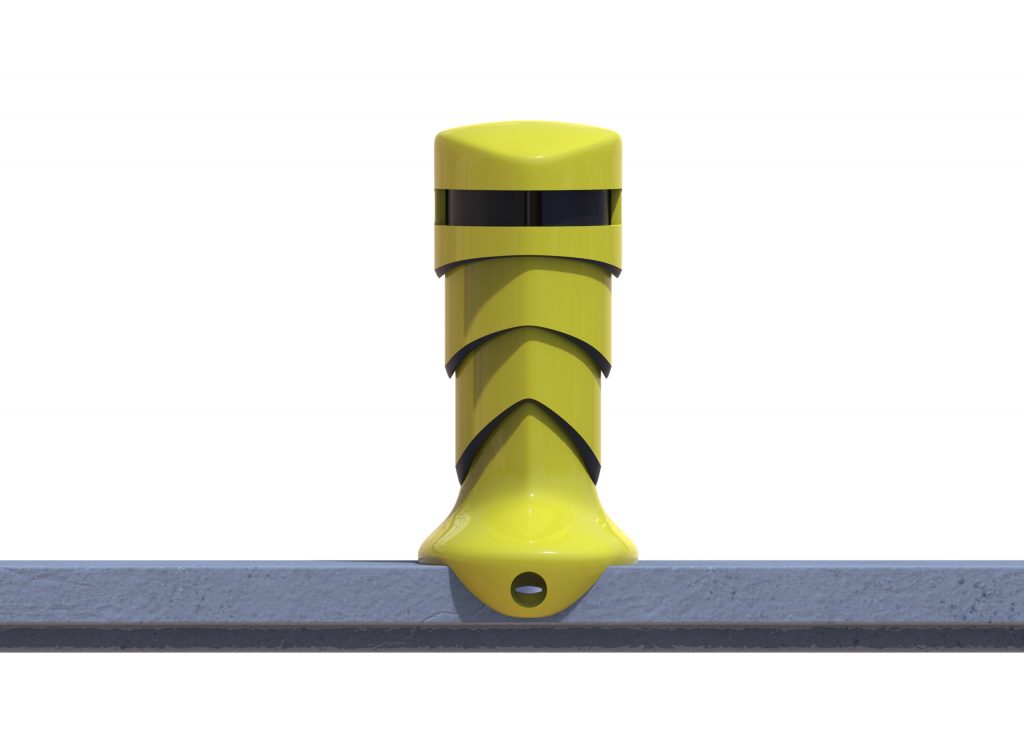

Internet of Things (IoT) company, Vortex IoT, is preparing to launch its state-of-the-art Rail Optical Detection of Intrusions and Obstructions (RODIO) solution, together with Network Rail and Tata Steel.

On 9th and 10th September Vortex IoT, which specialises in creating innovative artificial intelligence (AI) solutions to a wide range of problems faced by businesses, will launch RODIO in front of around fifty rail industry experts. The brand-new technology has been designed to automatically and remotely detect and categorise track obstructions and intrusions such as fallen trees, landslides, trespassers, vehicles and maintenance workers.

Funded by Innovate UK, the RODIO solution has taken 18 months to develop from concept to its imminent launch and has endured vigorous testing at the Network Rail RIDC Tuxford (Rail Innovation & Development Centre) facility in Tuxford, Nottinghamshire.

Founded by managing director, Adrian Sutton (CEO), Behzad Heravi (CTO) and Nick Beckett (COO), Vortex IoT is made up of a team of engineers with expertise in emerging technologies, artificial intelligence (AI) and machine learning. Speaking in the run up to the launch, Adrian says: “Rail delays cost the industry millions of pounds every year.

The ground-breaking, cost-effective RODIO device will allow the industry to detect any obstacles that may interfere with train journeys in real-time and therefore deal with them in a timely manner and reduce the overall delay. The system also includes an early alert system for theft, trespass and intrusions and guarantees high precision even in low-visibility and dark conditions. We have worked closely with Network Rail and Tata Steel for more than a year to bring this product to fruition and look forward to launching it in September.”

Gregan Quick, Network Rail R,D&T project manager, adds: “Network Rail welcomes technological advances in safety, and putting passengers and freights users first. RIDC Tuxford is facilitating the trial of this IoT based solution.”

Gareth Osmond MIET, software development manager Process Control & Automation for Tata Steel comments: “The RODIO product is an ideal fit for Tata Steel. As a heavy manufacturing organisation we are reliant on rail; it is both integrated into our production plants and – from a logistics perspective – we have one of the largest private rail networks in Europe all geared toward market and supply chain fulfilment.”

“The opportunity to get involved as a partner in the RODIO project was a simple choice for Tata Steel and the work done by Vortex IoT has been exemplary. We look forward to working with the team and wish them well with the product launch.”

Alongside RODIO, Vortex has also developed IoT-based solutions including a secure, self-healing mesh network, an Air Quality Measurement (AQM) platform and integrated smart parking optimisation. Its developments often provide a solution for harsh environments where conditions are hostile, power supply is limited, AI is needed, or data security is critical.

Comment on this article below or via Twitter @IoTGN