Breakthrough sensors: Fugitive hydrocarbon detection utilising cloud based IoT Gas Activated Systems at Texas Tech University

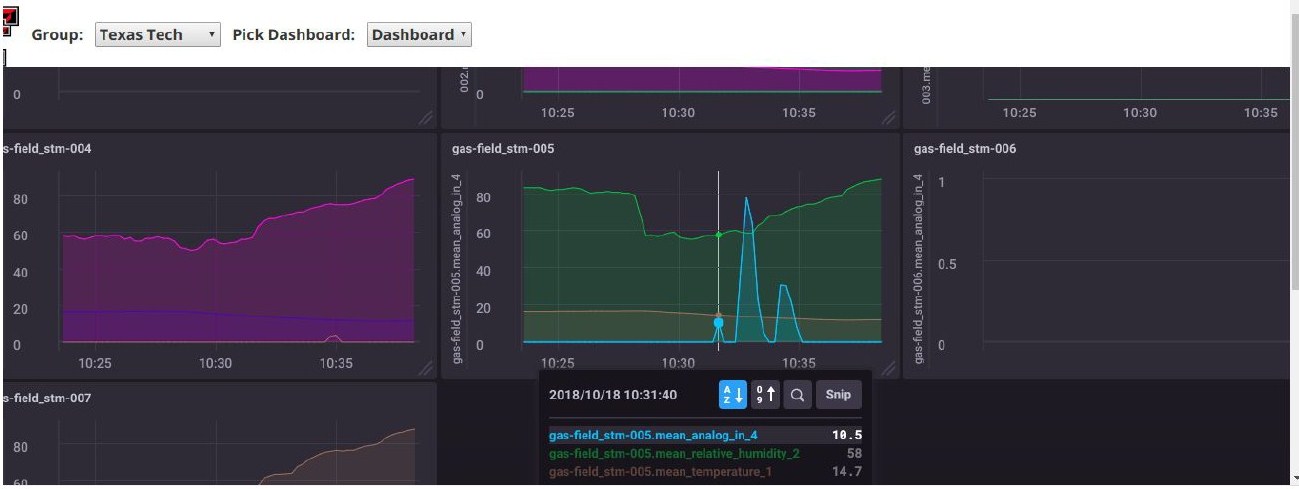

The Petroleum Engineering Department at Texas Tech University conducted testing on the Gas Activated Systems suite of cloud-based fugitive hydrocarbon detection tools. DetectSys–a system utilising breakthrough multi-species gas quantification in a single sensor–complete with geolocation and long-range wireless communications, was exposed to methane in field-encountered conditions.The immediate output was observed via the PreventSys platform via real-time dashboards and captured in the cloud-based time-series database.

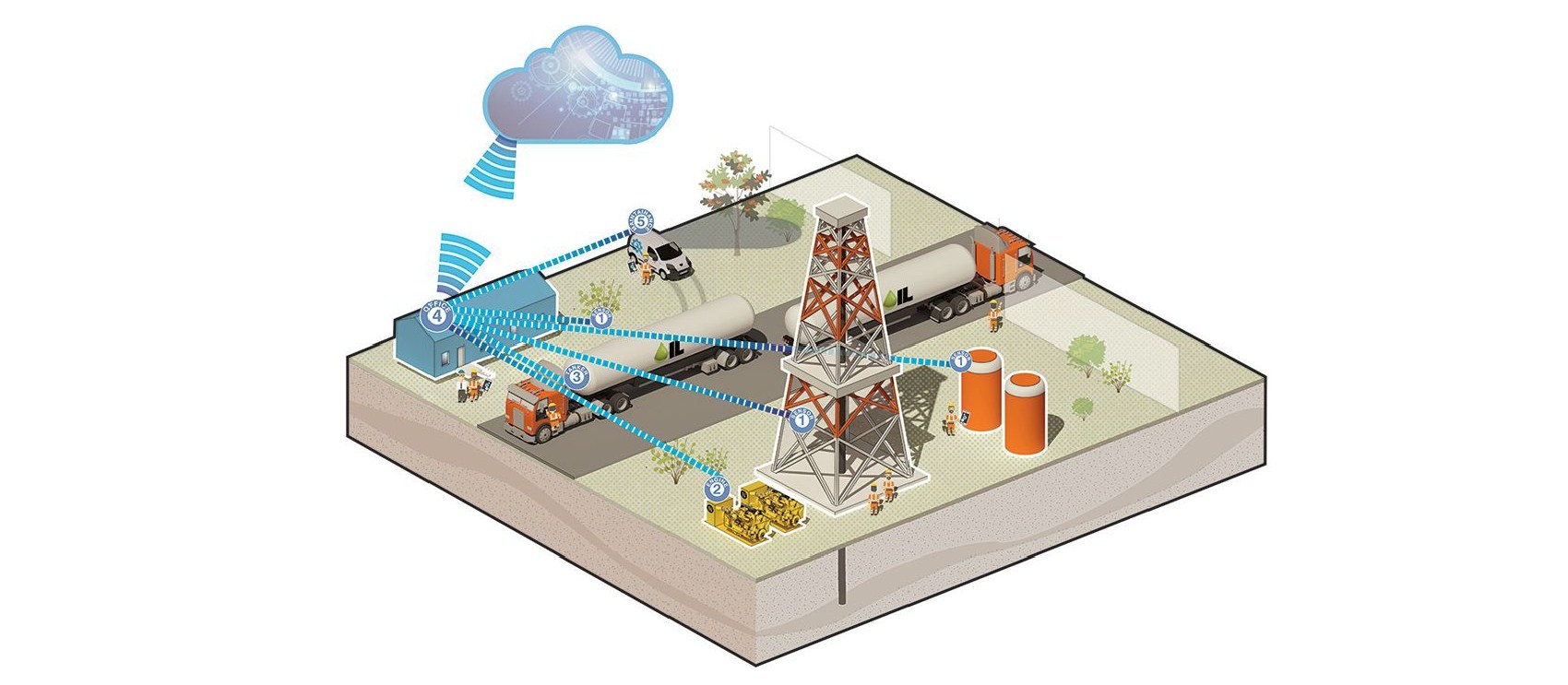

Gas Activated Systems uses its advanced Industrial Internet of Things infrastructure that includes state-of-the-art MEMS-based, silicon sensor technologies to identify and quantify multi-species gas emissions at oil and gas exploration and production sites, refineries, storage and transmission facilities. Through this system, gas emissions can be monitored, mapped and analysed 24/7 in real-time, providing the intelligence necessary for immediate remediation of methane and other combustible emission sources.

Oil and gas companies require methods to monitor derogatory events throughout their processes. Upstream, midstream and downstream, there are significant threats to life and property. Preventative and predictive solutions will increase reliability and maintenance, production optimisation, field development, collaboration and safety. Unintended gas releases on oil or gas production sites contribute not only to the hydrocarbon emissions of collective.

Greenhouse Gases, but also pose immediate risk for explosions when in contact with combustion sources. Currently there is no system that can accurately report a plurality of hydrocarbon LEL (lower explosive limit) concentrations using a single sensor. The MEMS sensor provided by Gas Activated Systems allows for speed, compactness, economy and robustness of service.

“Our platform provides explosive and combustible gas detection of a multitude of gases using a single sensor, complete with time-series database population for immediate and forensic discovery. The cloud-based structure allows for 24/7, real-time alerting, autonomous action and remediation” stated Michael Bryan, Gas Activated Systems CEO.

The tests were conducted at the Oilfield Technology Centre, an extended lab functioning oil field located on the University’s East Research Campus. Methane was manually released and then verified via infrared camera. The sensors were evaluated for their prompt reading and reporting of correct gas LEL. The resulting data demonstrated that the Gas Activated Systems hydrocarbon sensing provided cloud reporting faster than the standard individual hand-held (local-only reporting) tools used in the industry today.

“We have demonstrated that Gas Activated Systems outperforms speed of detection of industry-standard conventional detectors,” says Dr. Ekarit Panacharoensawad, assistant professor, Bob L. Herd Department of Petroleum Engineering. The second part of the product validation was systematic testing of DetectSys, alternately applying precision calibration methane and propane. Panacharaoensawad added, “The Gas Activated Systems’ units provided accurate %LEL readings, again beating the industry-standard handheld device by nearly 50%.”

Denny Bullard, instructor at the Department of Petroleum Engineering and a 50 year member of the Society of Petroleum Engineers adds, “Using the LoRaWAN wireless, the data communications were measured at full strength back to the gateway even at distances beyond 500 feet.”

Located on the east side of Lubbock, TX just outside the city limit, OTC provides class room training and research space for both academic and industry needs. It has a 4000 foot test well equipped with a pumping unit connected with a flowline to a surface tank battery for demonstration and training purposes. Furthermore, high pressure separator and gas processing units including a line heater, vapor recovery unit, high pressure and low pressure natural gas compressors, and a vapor recovery tower are part of the OTC that is used for training and other academic needs.

Comment on this article below or via Twitter @IoTGN