The benefits of adapting IIoT and data analytics solutions for EHS

Jagan Garimella, CTO of ProcessMAP

The IIoT (Industrial Internet of Things) improves connectivity, efficiency and scalability for industrial organisations. Combined with the power of big data and analytics, the IIoT is an incredibly powerful concept that drives in-depth insights for organisations.Many companies are already leveraging IIoT and data analytics with remarkable success in core operations and achieving significant results in time and cost savings.

One application of the IIoT that can make an equally impactful mark on a business is the management of environmental health and safety (EHS) risks. EHS risk management focuses on protecting employees, the public and the environment from harm. This risk focus is in the form of reducing the probability of an incident occurring and its consequences or adverse effects, says Jagan Garimella, CTO of ProcessMAP.

With the number of connected devices expected to reach upward of 100 billion by 2025, the opportunities to use such devices effectively to help manage EHS only continues to increase. Connected technology can enhance EHS management practices and by embracing the IIoT for EHS, companies can take advantage of new opportunities to reduce the risk of injury to workers and harmful impacts to the environment.

Let’s delve into what benefits IIoT and data analytics provide from an EHS risk management perspective:

- Asset management and maintenance: IIoT can provide immediate updates on the performance and safety status of facility and production assets. With sensors connected to a business’s most critical assets, large volumes of accurate data can be collected for real-time monitoring and analysis which can help prevent failures before they happen to propel asset performance improvements. For instance, a recent study determined that companies that are Top Quartile performers with condition-based, planned maintenance have fewer equipment emergencies resulting in 71 % lower maintenance cost and 14 % less downtime.

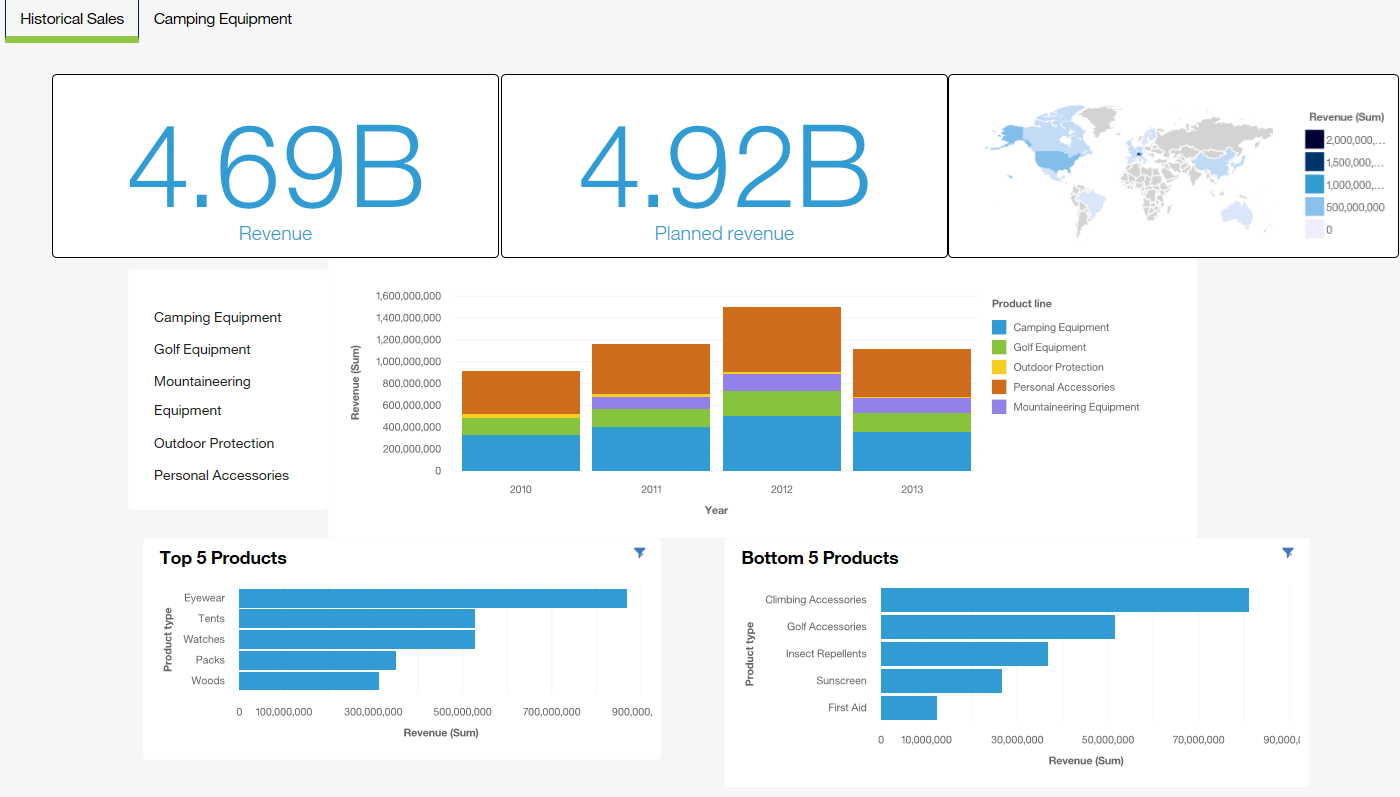

- Next-level business intelligence: IIoT can serve as a forecasting tool for more informed EHS management and decision making by constantly monitoring, aggregating and analysing data from various sensors. These sensors can be installed across a connected plant or workplace and provide real-time data allowing companies to obtain insights to various operations and initiate preventative actions. For example, IoT sensors are often installed to measure parametres at remote or high-risk maintenance infrastructure that is difficult or dangerous to physically access. Such infrastructure can be situated below the surface, atop high terrain, or even in isolated areas. Data from these places allows companies to prepare for emergency planning, maintenance and compliance activities.

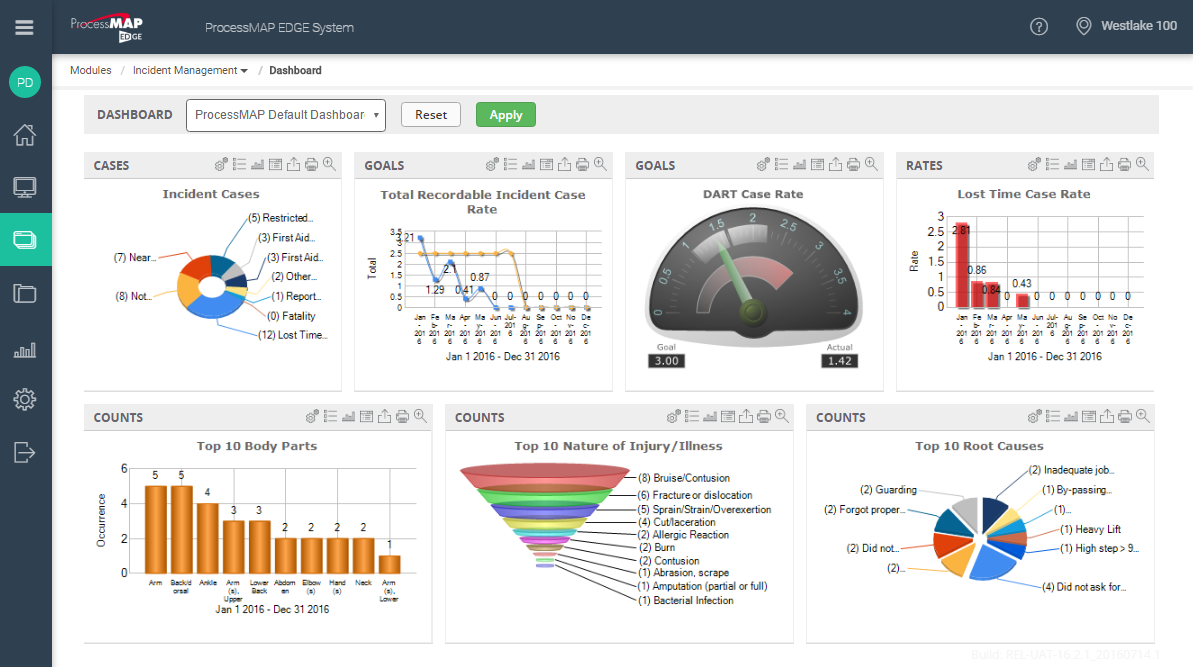

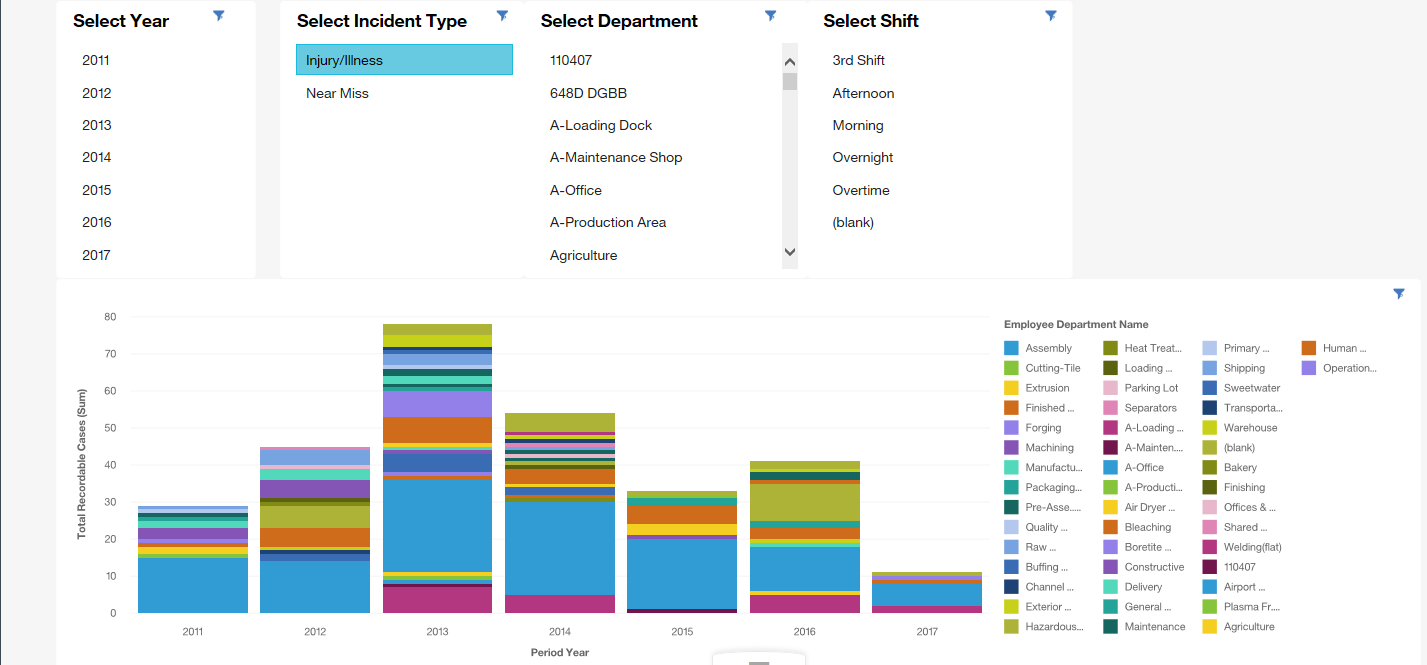

- Risk mitigation with actionable insights: IIoT can provide terabytes of data from device monitoring and incident information. This data can be analysed to decipher key trends and required actions to help mitigate the risk of potential future incidents. With IIoT and data analytics, businesses can enable corrective and preventative actions more quickly and accurately. For instance, managers can establish patterns where and how incidents are occurring and, with the data analysis, predict potential future re-occurrences and determine the best plans of action for risk mitigation.

The business case for IIoT for EHS is clear, so what can companies do to pursue an IIoT-enabled solution?

Though IIoT is still an early technology, it is improving rapidly and, more importantly, changing every day. As such, companies should be judicious if looking to invest in a full IIoT solution right away without considering the nuances involved with such a fast-evolving technology.

The best approach is to start small and slow by picking one area – connected assets, wearables, software architecture, etc. – of IIoT enablement to optimise uses, and then focus on building an IIoT platform from there. Systematically adding new areas of functionality with robust data analytics will allow organisations to grow the platform organically while slowly integrating IIoT enablement into any existing EHS processes.

After implementation, companies could setup well-defined metrics and goals for incident prevention for example, and then work to meet those goals while increasing the scale of deployment for IIoT. According to Intel, IIoT for asset management can boost production by an estimated 5-25 % and increase asset utilisation by 3-5 %. These can be valuable benchmarks for an organisation to evaluate its progress.

Most importantly, technology alone cannot solve every business issue when it comes to EHS risk management. IIoT and data analytics for EHS are tools managers can use to forecast threats, collect data, and ultimately make better decisions. To move to a zero-incident culture, companies must also have a comprehensive EHS strategy and protocols in place and use IIoT to gain further insight and enhance safety measures within an organisation.

Nonetheless, with the right people, right strategy, and right technology courtesy of IIoT, any company regardless of size can make great strides in environmental health and safety as long as they remember that a steady and methodical approach is best.

The author of this blog is Jagan Garimella, CTO of ProcessMAP

Comment on this article below or via Twitter @IoTGN