What’s so special about today’s Industrial IoT sensors for monitoring your air, water, or anything else?

Dr. Edward Pultar, founder of Valarm

You and your family’s air quality / pollution is becoming a bigger challenge every day. Millions of people die every year from issues caused by air quality and pollution. And clean water becomes more of a global issue with each passing day.

How can the Industrial Internet of Things help remotely monitor you and your family’s air, water, or anything else that’s important to you?

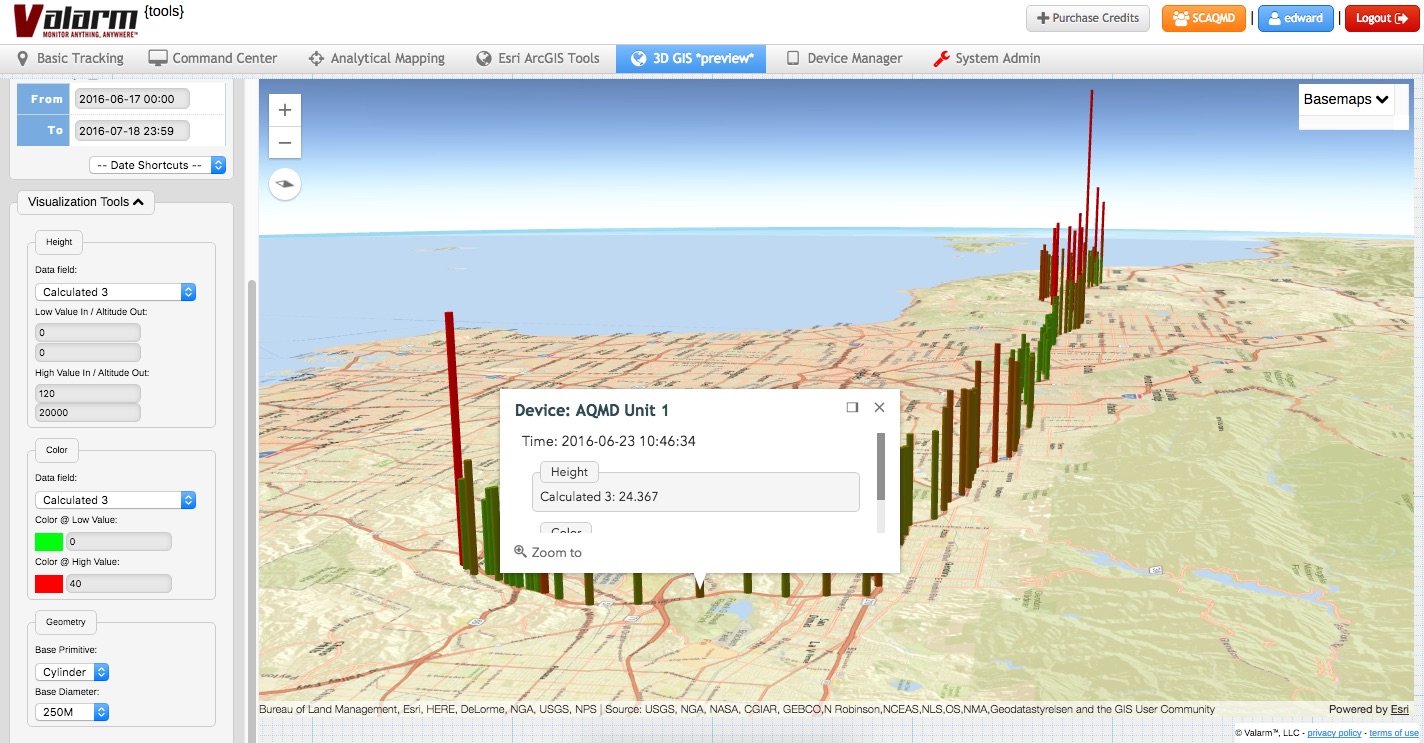

IoT devices, software, and gateway provide an automatic sensor telemetry platform for remotely monitoring just about anything, anywhere. Now what’s so special about today’s IoT devices?

Let’s talk about a few key advantages for IoT with air quality monitoring vs. the technologies we had 10 years ago:

- Price

- Size

- Connectivity

The ever-expanding number of IoT hardware manufacturers around the world means the price deploying IoT sensors is quite cost-effective right now. Like computers and other technology, it’s surprising how you can pay half the price, or less, for a sensor than you would have a couple years earlier, says Dr. Edward Pultar, founder of Valarm.

The ever-expanding number of IoT hardware manufacturers around the world means the price deploying IoT sensors is quite cost-effective right now. Like computers and other technology, it’s surprising how you can pay half the price, or less, for a sensor than you would have a couple years earlier, says Dr. Edward Pultar, founder of Valarm.

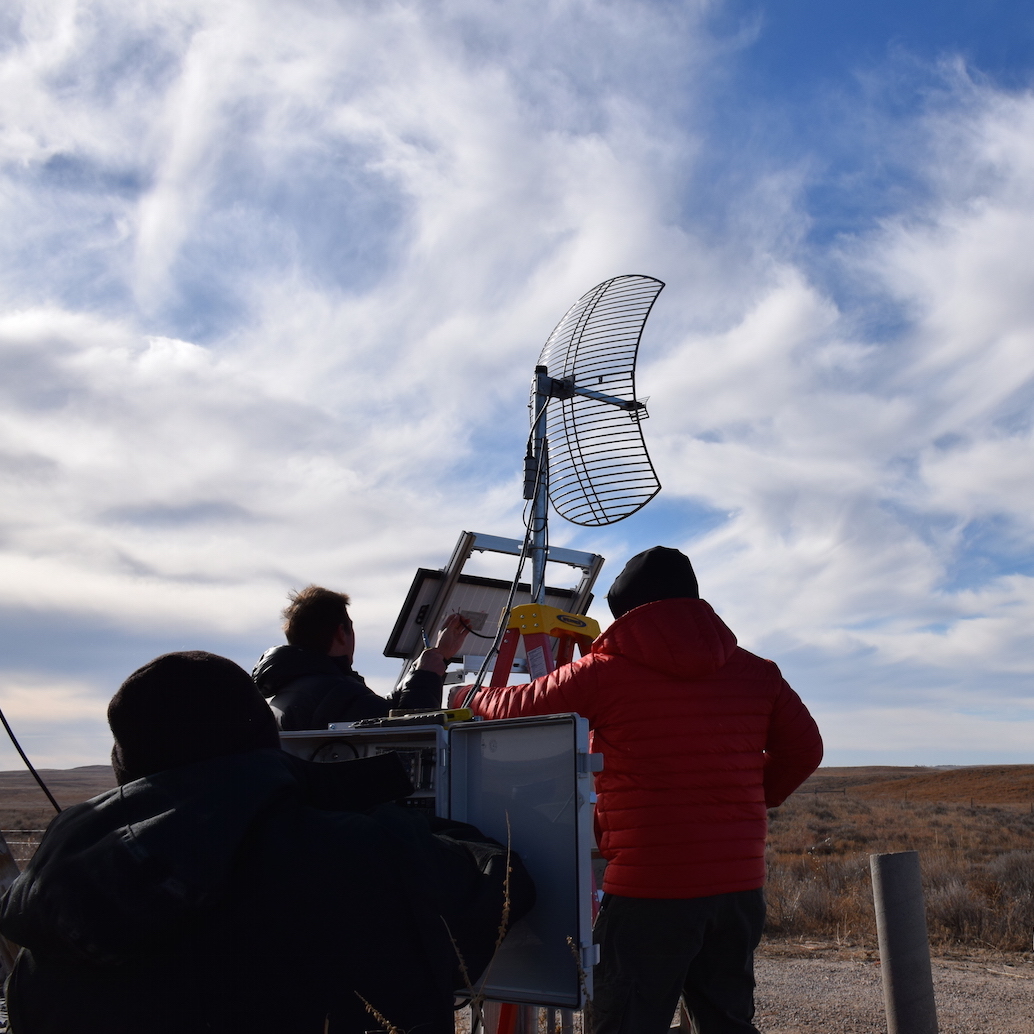

As technologies and sensors are refined, gigantic sensors that used to be the size of a refrigerator now fit in the palm of your hand! Well maybe that’s a little exaggerated, but it’s just like computers and the majority of technology, sizes as well as costs are reduced over time.

You’ve got more Internet connectivity options than ever for sending IoT sensor readings to the clouds for alerting, mapping, visualising, and business analytics. The old standards that have been around for many years, like Wi-Fi, Ethernet, and GSM cell networks, are trusted, well understood, affordable, and widely available. It’s quite impressive how excellent of a fit these older networking technologies are for Industrial IoT.

Sometimes you think you need the latest and greatest, but Ethernet connectivity works incredibly for monitoring stationary industrial assets & equipment, like tank levels & volumes. And this saves you a lot of money since you’re not paying any additional monthly fees!

Similarly with Wi-Fi, if you’ve already got Internet access at the location you need to monitor then why buy or add anything else? Sometimes with just a simple Wi-Fi antenna you can increase connectivity for the region you need to monitor with Industrial IoT. Again you won’t need to pay any additional monthly fees, which helps your bottom line tremendously.

New networking technologies, specifically for IoT sensor devices, seem to be popping up more and more, like LoRa, Sigfox, and Ingenu. And while there won’t be a clear winner any time soon, at least you’ve got options so you can choose which IoT technologies make the most sense for each of your specific remote monitoring deployments.

More and more with each passing hour of your life, you’ll see an increase in businesses and organisations adopting Industrial IoT sensors for remote monitoring applications. The organisations that take this leap will get improvements in their bottom line, increased safety, and decreased waste.

Of course there’s never another time like the present, but Industrial IoT (IIoT) devices, software, and applications are ripe for deployments. Whether you and your teams need to monitor air, water, fleet vehicles, trucks, trailers, pumps, vacuums, tanks, wells, generators, motors, industrial equipment, or any other assets, IIoT effectively manages what’s most important to you.

The number of IIoT customer success stories goes up every day. Deploying the Industrial Internet of Things has never been quicker or easier. And with such amazing returns and advantages, it’s an exciting time for IoT. Are you ready for IoT, or already using it, or perhaps you’ve got ideas on new applications?

The author of this blog is Dr. Edward Pultar, founder of Valarm

Comment on this article below or via Twitter @IoTGN