Digital twins: The fast track to increased productivity

Maurizio Canton, CTO EMEA for TIBCO Software

Digital twins are not a new thing. Companies have been using a virtual representation of a physical asset for years, but it’s only with the Internet of Things that they’ve become truly accessible and cost-effective.

Essentially the role of the digital twin is to bridge the gap between the physical and digital world and by crossing that bridge, more companies are harnessing these digital doppelgangers to achieve the twin effect of boosting productivity and cutting waste.

Traditionally the only way to monitor production equipment was through physical monitoring of mechanical results. This was of course vastly labour-intensive and resulted in a significant drain on time. However, its main drawback was the fact that it gave designers few chances to change their prototype. With opportunities for changes during the process limited, the finished product could often not be fit for purpose, resulting in massive expense and time wasted, says Maurizio Canton, CTO EMEA for TIBCO Software.

The twins are born

Today micro-sensors and software have combined to create a system of micro-management for manufacturing production lines which has reaped substantial efficiency dividends. These savings and advances are achieved through a joint operation, where these twin forces measure every tiny aspect of a physical device and use this intelligence to recreate it in digital form, somewhere in the cloud. This virtual representation of each physical device is known as its digital twin.

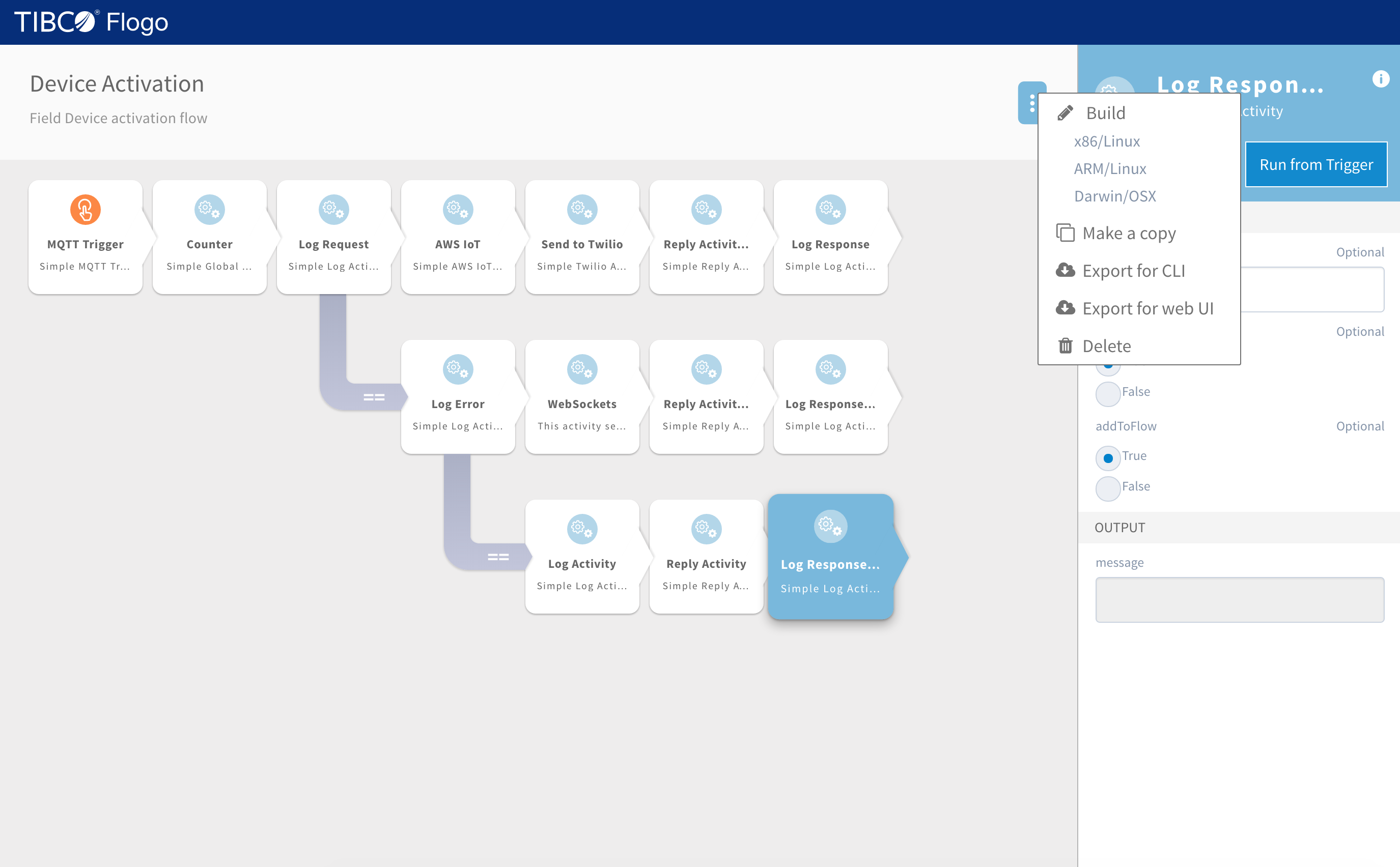

Flogo Screen Shot – Device Activation

Having digitally twinned a device, manufacturers are afforded the luxury of being able to test it and amend it through the entirety of the production process. The ‘virtual modelling’ means that once a prototype is ready for manufacture, it will be much closer to perfection than under the old system. The fine tuning does not stop there, as intelligence can be fed back from the product throughout its lifetime.

This means that manufacturers are then able to not only reduce development time and costs, but to also move into the area of being able to predict failure scenarios and potential downtime – and insight that provides a significant and valuable step forward.

Overcoming complexity

The entire production system can benefit from the efficiencies of digital twinning and when one vendor has complete dominance of a vertical market the digital twin approach is relatively easy. However, if these benefits could be extended to the entire supply chain, the gains could be enjoyed by the wider economy. But this doesn’t come without its challenges; in fact, the involvement of multiple vendors and new manufacturing techniques makes for a far more challenging environment.

So, how can these complexities be overcome? First and foremost, it is imperative to assist small suppliers as they look to adopt a digital approach. One such example in the US is the government’s Digital Manufacturing and Design Innovation Institute (DMDII), which is funding an appeal for examples of digital twinning by supply-chain participants. If all supply chain participants commit to adopting digital-twin models with their suppliers and partners, the mutual benefits could be immense.

Machine to machine harmony

It is the need for machine-to-machine harmony that has inspired vendors such as TIBCO to make strides in integrating devices made for the IoT.

The two pillars on which TIBCO’s strategy is built are Project Flogo and the TIBCO Graph Database. Project Flogo is ultra-lightweight integration software, which is designed to fit the tiniest of spaces and, through the open nature of its source code, it aims to work with anything.

The minimal presence doesn’t stop it from referencing the powerful translytical Graph Database. The rationale behind this referencing is to give developers the broadest possible range of options when creating IoT environments. The TIBCO Graph Database creates all these possibilities through its signature specialist function. This makes sense of a complex web of dynamic data and translates it into intelligence that can be rationalised and acted upon instantly. Such a combination not only increases interconnectivity, but augments the intelligence of the IoT.

The digital twin is very much a child of Industry 4.0, the rise in Big Data and the Internet of Things. Indeed, the impact of the digital twin has been massively boosted by recent breakthroughs in industrial connectivity and machine intelligence and will continue to be the technology of choice for digitalising the physical world.

The author of this blog is Maurizio Canton, CTO EMEA for TIBCO Software

Comment on this article below or via Twitter @IoTGN